Embedded Intelligent Laser Marking Scanning Control System

Features

1.Powerful gigabit, ultra-high-performance hardware

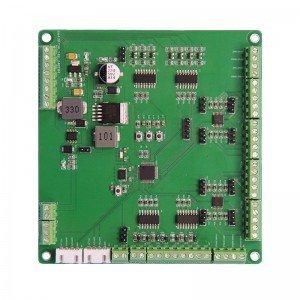

Am logic S905X3 quad-core Cortex-A55 (2.0xxGHz) processor, 4GB LPDDR4 and 16G eMMC onboard storage, 4 USB 3.0 ports, 1 Gigabit Ethernet port, ARM is responsible for graphics data processing, FPGA is responsible for point interpolation and data correction algorithms, as well as galvo head and laser control

2.Linux software system, laser control integration

It can carry out secondary development through the network port or serial port (USB to 232), and transmit simple parameter instructions to realize the laser control system integration of complex systems.

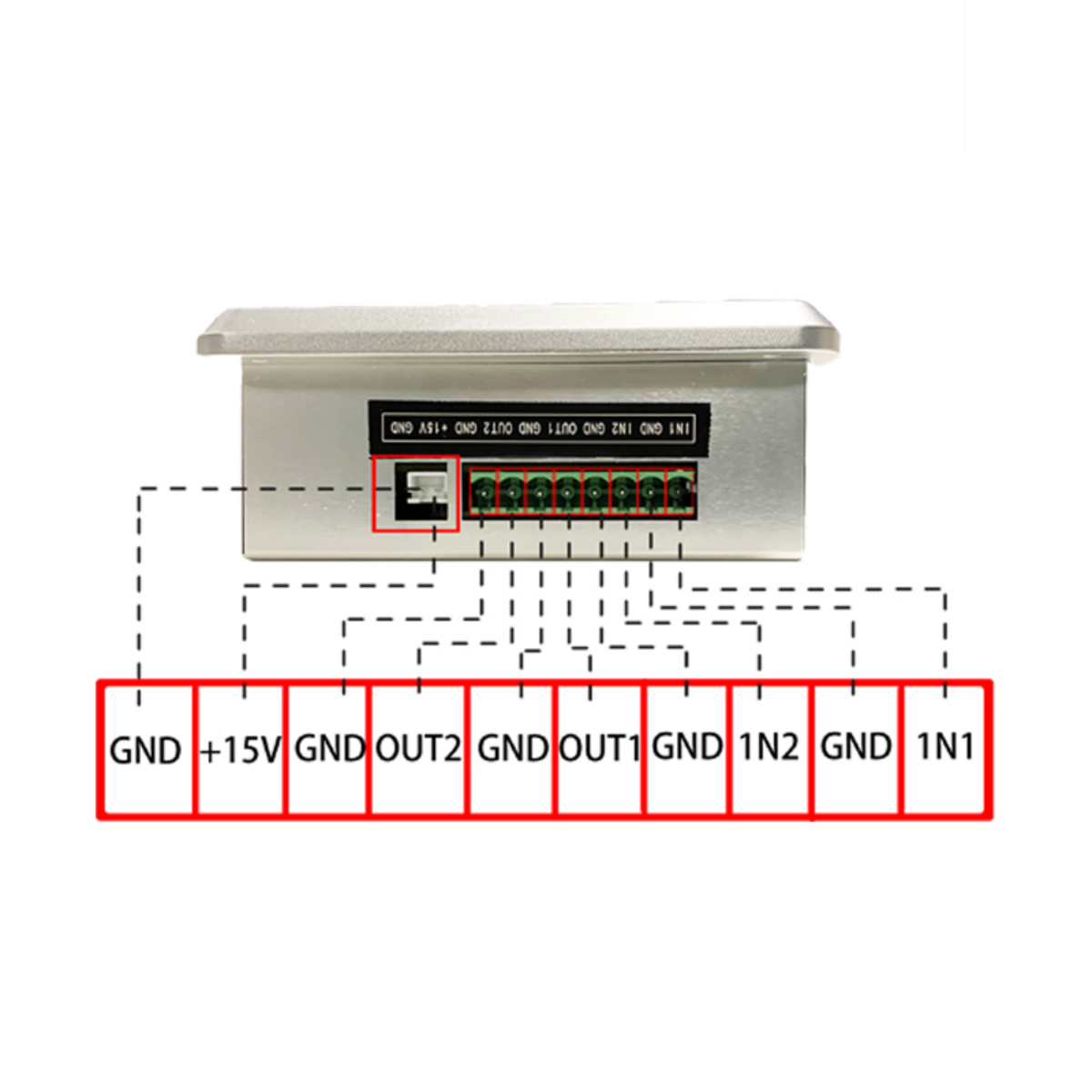

3.IO control, remotely activate marking

Supports control of XY2-100 protocol galvo heads, fiber lasers such as IPG, JPT, and CO2 lasers as well as UV laser.

4.Highly integrated system, network port remote login

Provide a remote login tool, which can remotely log in to the graphical operation interface to control functions such as marking

5.Smartphone APP is more convenient and faster

Provide a complete secondary development protocol (modification of graphics, galvo heads, laser and other parameters)

Application

Embedded laser marking scanning control system can be used for logo marks, serial numbers, bar codes, and other beautiful patterns on any metallic materials such as stainless steel, aluminum, titanium, brass, gold, silver, aluminum, and lots of engineering plastic products such as mobile cover and charger, consume electronics housing and so on. It is more comprehensive than normal laser marking control system, operation is easier.

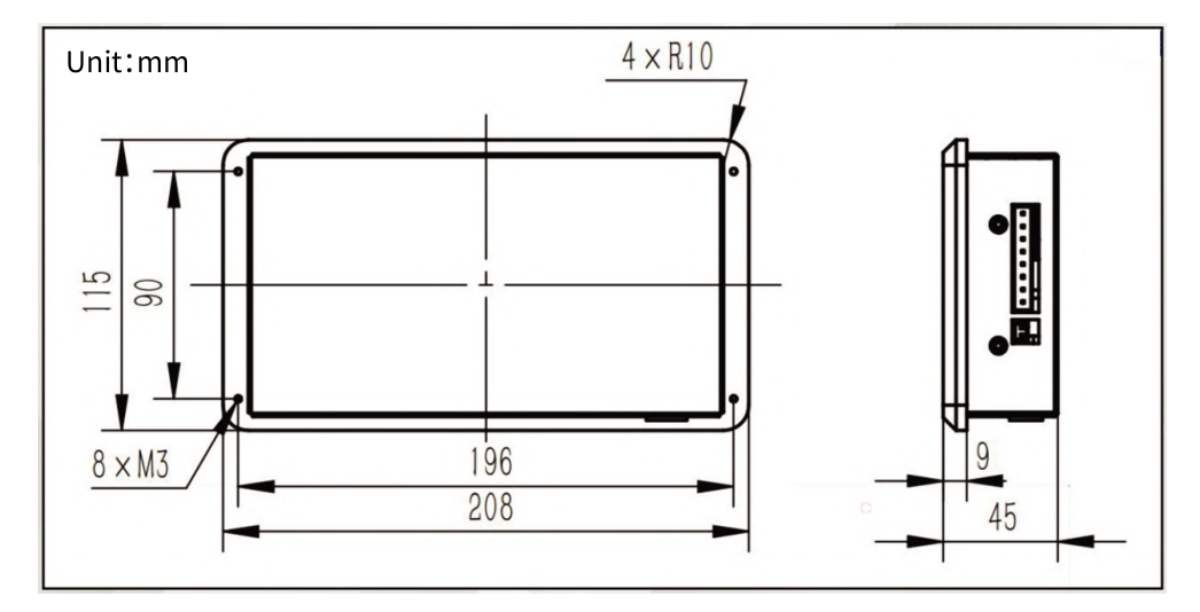

Structural Parameters